This is Canakva

Canakva will operate a flow through fish farm located on the East Coast of Canada in Nova Scotia with free access to large volumes of tempered sea water.

Pioneer farm from 1990’s provides the infrastructure for repurposing to state-of-the-art 2025 fish farm.

Canakva will focus on a flexible farm concept, capable of producing both post-smolt and full-grown salmon.

Current plans are to update present facility to 2.500 tons and to prepare for scale up to 14.800 tons production.

Post smolt strategy defined

Post-smolt

Post-smolt refers to a salmon that has been transferred to saltwater and has begun its growth phase in sea pens or ocean farms.

Post-smolt strategies

New post-smolt strategies aim to shorten the sea-based grow-out phase. Post-smolt salmon are transferred to the sea at a larger and more robust size to enhance fish survival, fish health, and overall fish welfare.

This is now considered a best practice in Norwegian salmon farming. In 2022, it constituted 21% of all Norwegian smolt releases in terms of individuals.

In Canada larger post-smolt strategy is being endorsed by local authorities:

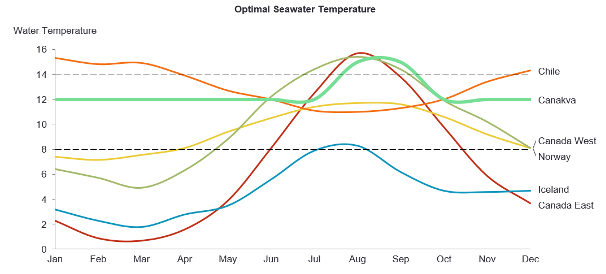

Competitive advantage: Access to tempered seawater (at low cost)

Blended water intake

Higher Lingan sea water temperature in summer months to be regulated through a new water inlet tunnel, bringing colder water into the farm (part of investment plan).

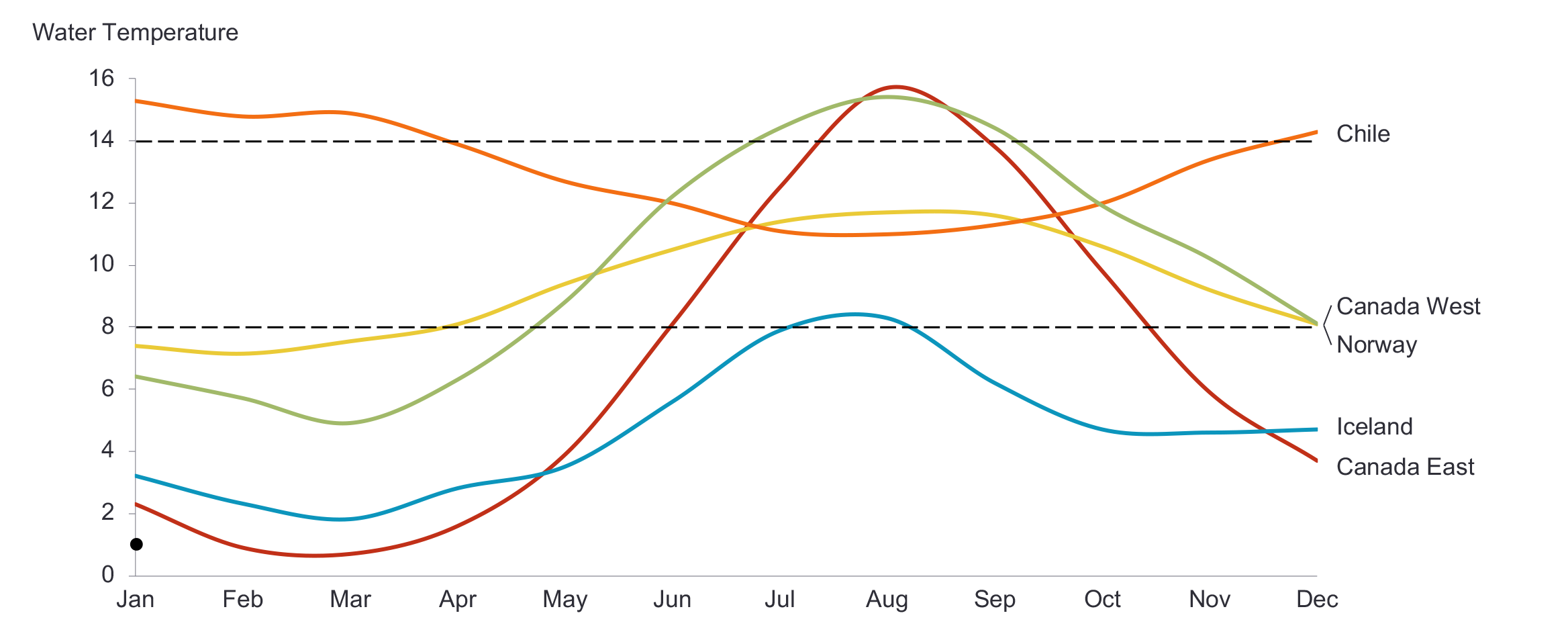

Optimized water temperature

Together with optimized nutrition, temperature is a primary growth driver for salmon. Salmon will grow at a range of temperatures, but growth will slow if the water is too cold or too warm.

Atlantic salmon typically grow at temperatures between 4 – 18°C, and heat stress begins to occur around 16 – 18°C. Heat stress can cause salmon to stop eating, resulting in reduced growth, and warmer temperatures eventually become lethal.

Energy Requirements

In land-based salmon farming, the highest energy use comes from maintaining water quality and temperature, especially in Recirculating Aquaculture Systems (RAS), which require constant circulation, filtration, oxygenation, and regulation.

Up to 8kWh of energy can be required to produce one kilogram of Hybrid Flow Through System salmon, depending on the systems used. In contrast, the marine stage of traditional salmon farming has negligible energy use.

Access to multiple water sources

Lingan farm access to tempered seawater (cooling water from power plant) gives the company an energy advantage over other flow through systems. Free access to max. 230.000 liter a minute of warm water, enough for 22,000 tons harvest per year [HOG]). Optimizing water temperatures can reduce the overall time to harvest with 3-4 months and will increase the farm production output.

CO2 benefits

The Lingan plan has a low Carbon Footprint, with as key driver the use of warm (waste) water from the Lingan power plant, eliminating the need for water heating and substantially lowering the overall CO2.